Construction Made Simple

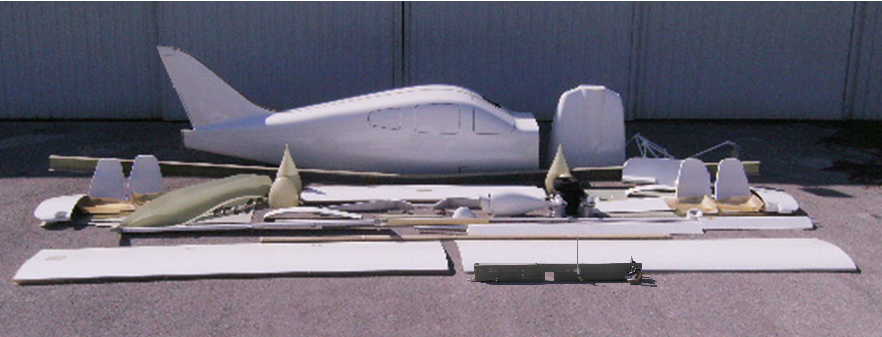

Team Tango designed both the Tango 2 and the Foxtrot 4 from the beginning as fast build kits to be built in a build center to minimize airframe build time. We make as many large, one piece components as we can to reduce assembly steps. We also gel coat the majority of our parts so they come out of the mold glossy white, requiring minimal finishing instead of hours of filling and sanding to prep for painting.

Follow through the airframe construction process to understand how you can build your airframe in approximately 1000-1500 hours.

FUSELAGE AND SPAR: The fuselage comes out of the mold in one piece. Set it on a stand, fill the outside seam and it is ready for the one piece spar. The one piece spar weighs less for the same strength and eliminates several assembly steps. For homebuild project, please contact us to ensure you have adequate space for the one piece spar.

LOWER WING SKIN, RIBS, AND FUEL SYSTEM: Once the spar is glassed in it is time to glass on the bottom wing skin, ribs, the fuel system, and glass in the main landing gear, struts etc.

TOP WING SKINS: The one piece top wing skins finish the basic wing structure. Line things up, apply thickened resin and set it in place. Simple clamps and clecos hold alignment until the resin cures. Add about an hour of filling and sanding on the leading edge and the wing is nearly perfect.

FLIGHT CONTROL SURFACES: All primary flight control surfaces are pre-assembled and ready for counter balancing and final finishing. The flaps and ailerons are attached to the wings with self lubricating bearings and actuated with torque tubes.

TAIL SURFACES: The banjo gets glassed in with the rudder brackets mounted. A sturdy cross tube holds the stabilator bracket.

TUNNEL: The flight control system is preassembled in the tunnel which is then glassed in as a single unit.

This constitutes the majority of the air frame construction. The remaining details include fitting the doors, installing the glass, and fitting the wing tips.